RogRacer gave everyone the definitive knock sensor DIY a few months ago. I just replaced mine following his instructions and thought I would add a few things to help the next person looking at how to do this. This is a fairly major job, but it is an excellent time to replace the fuel filter and clean the ICV, etc.

The usual caveats: All credit is due to RogRacer for the original DIY; proceed at your own risk according to your abilities; YMMV, etc.

My additions are in

blue.

___________________________

From RogRacer's writeup:

Knock Sensor Installation Instructions for ’95 M3

Approach

These instructions will explain how to replace the knock sensors on a ’95 US-Spec E36 M3 using the "from above" approach that requires removal of the intake manifold. On late-build ’95 M3s and beyond, it may be possible to replace the knock sensors using the "from below" approach by removing the starter and a few other things, but that approach is not possible on early-build cars like mine.

These instructions will explain the "from above" approach as was required on my early-build ’95 M3. These instructions may also be useful for any early M50, and perhaps M52s if using the "from above" approach, but as always, YMMV. (As a side note, if you just need to replace the number 1 sensor, you can get to it without removing the manifold and you can skip all this stuff)

Other cars may differ, but there is no way that this could be done on my car. I had to take the manifold and ICV off to get to the connector - even for #1.

Parts

Two (2) knock sensors. You’d be nuts to replace just one sensor if you’re going to the trouble of removing the manifold

(no kidding!!). They’re only about 50 bucks each. I’d also suggest new manifold gaskets and a new throttle body gasket. You may also want a new set of fuel-injector O-rings, but I didn’t bother. You’ll also need some new hose-clamps for the fuel lines. This is also a good time to put in a new fuel filter so you might also want to get one of those too.

Also - be prepared to replace vacuum line on the fuel pressure regulator - it cracks with age/heat.

Tools

Just the usual assorted wrenches, sockets (mostly 10 and 13 mm), extensions and swivels. You’ll also want an inspection mirror, a magnet to pick up dropped fasteners, and some petroleum jelly.

Instructions

1) Remove the #18 fuse to kill the fuel pump and try to start the car. The car will not start, but the fuel system will depressurize.

Actually mine started and ran for about 15 seconds.

2) If you’re going to replace the fuel filter, you will need to get the car up on ramps or jack stands. Otherwise, you can perform the entire procedure with the car on the ground.

3) Disconnect the battery, because you’ll be working around the starter and alternator and welding is not part of any of these instructions.

(No kidding - the starter is RIGHT THERE and you will contact it.)

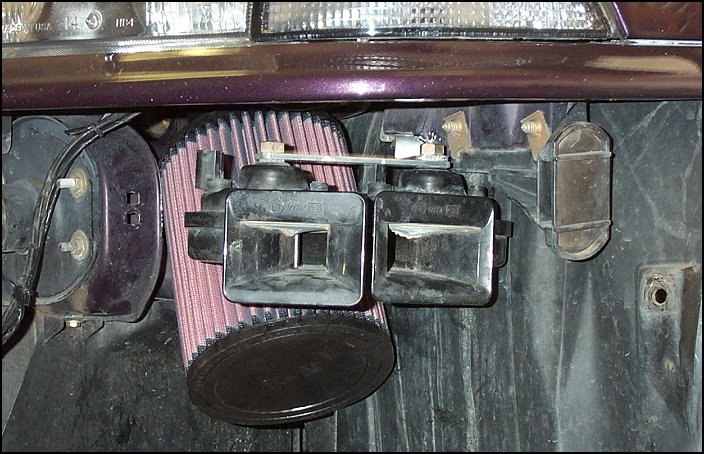

4) Remove the intake system from the filter all the way back to the throttle body.

5) Remove the alternator-cooling duct.

6) Remove the cosmetic plastic covers for the valve cover and fuel-injection harness.

7) If you’re replacing the fuel filter (on early build cars), this is a good time to do it. Get to the top filter clamp from above the car, and the lower one from below. Be prepared for a significant amount of fuel spillage with a catch-tray, but once the filter drains, the flow will stop. After the new filter is in, you can put the car back on the ground, but I left mine up on ramps because I found it useful to look at things from "underneath" at times, and to make collecting the dropped fasteners a little easier.

I found it easier to replace the fuel filter on my early build (8/94) AFTER I had the manifold off.

8) The next few steps (9-13) are all required so you can get to the rear most manifold nut, which is obscured by the fuel rail, the pressure regulator, and the wire harness box at the firewall. It is my understanding that some cars can access this nut without doing all this, so you may want to check before proceeding.

I think Roger's suggestion to do all of this is absolutely right and is the difference in making the job workable. This greatly improves access.

9) Remove the windshield wiper arms. On my car, this was easier said than done. The arms are pressed onto a spline and are a tight fit. You need to wiggle them while pulling them off. Mine were on so tight, I ended up using a puller, but you might get by with a screwdriver to pry them off.

10) Remove the plastic cowling beneath the wipers.

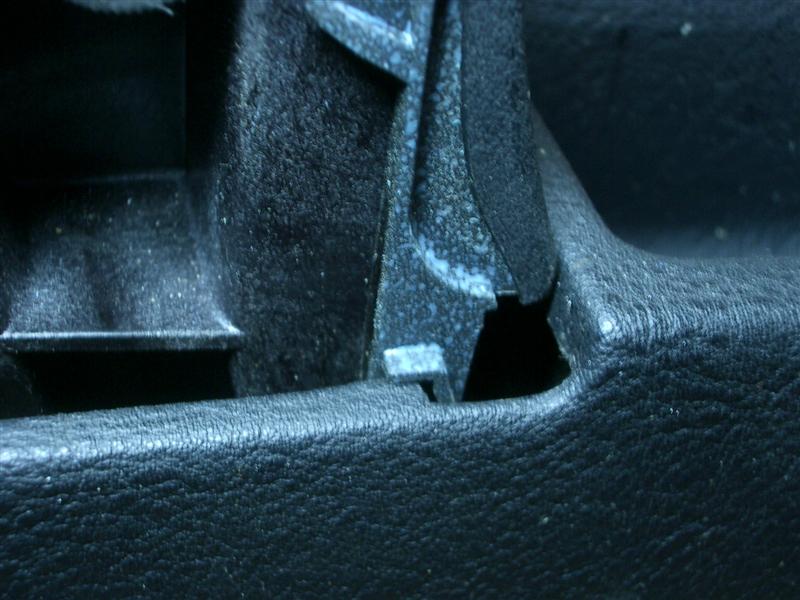

You don't have to remove it completely. I just removed the little screws holding down and lifted it up as needed. It is a pain to replace in the corners if you remove it all the way.

11) Remove the DME from it’s compartment in the firewall and separate it from the wire harness connector.

12) Unscrew the harness box from the lower cowling underneath the wipers.

13) Remove the lower cowling (2 screws on passenger side, one on the drivers).

Essential for easing the work in the rear of the manifold.

14) Cut the wire-tie above the brake booster, and pull the wire harness as far up off the manifold has possible to gain clearance with the rear most manifold nut. Temporarily secure the harness in this position with a tie-wrap or string.

15) Disconnect the electrical connector at the throttle body and unbolt the throttle body from the manifold. Leave the all the hoses attached to the throttle body.

16) Using the inspection mirror, look under the manifold at the Idle Control Valve vacuum hose attachment to the manifold. It is held in place with a finger-clip type latch. You press up on this latch while pulling the large hose out of the manifold, but, again, it is easier said than done. I needed to put a small flat- head screwdriver in the latch to help coax it out.

This was impossible for me to remove so I removed everything else, pulled the BACK end of this hose off the ICV, then took the manifold off, flipped it over and removed this as the last connection.

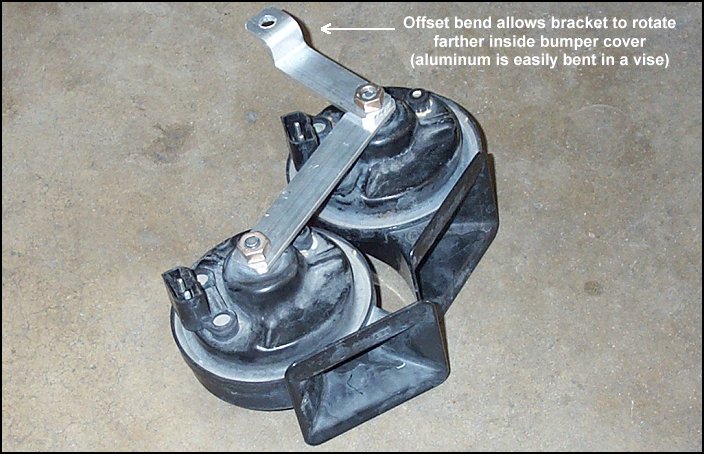

17) Remove the front and back side manifold support brackets.

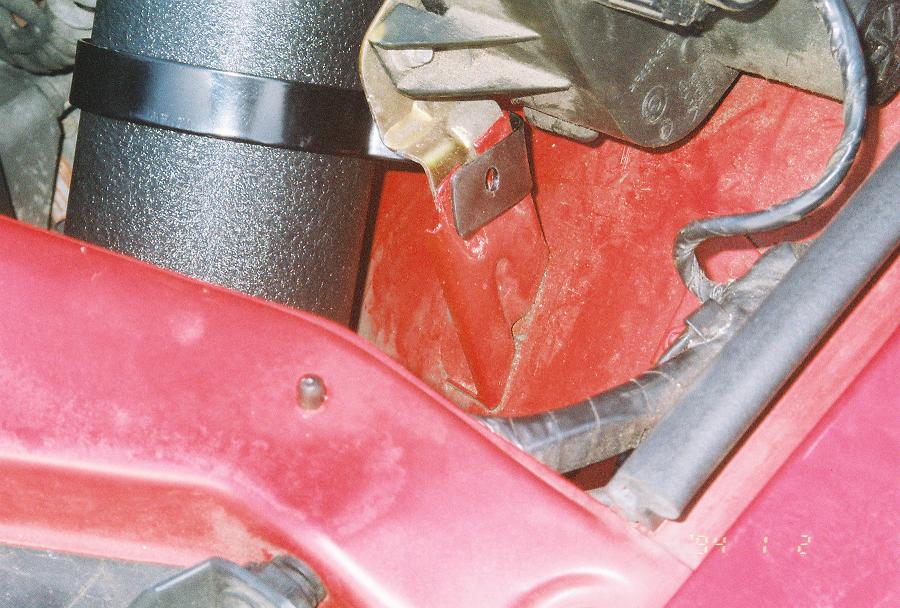

I removed the bolts that connect the brackets to the manifold. The rearmost one has another bracket sandwiched in with it than holds fuel lines.

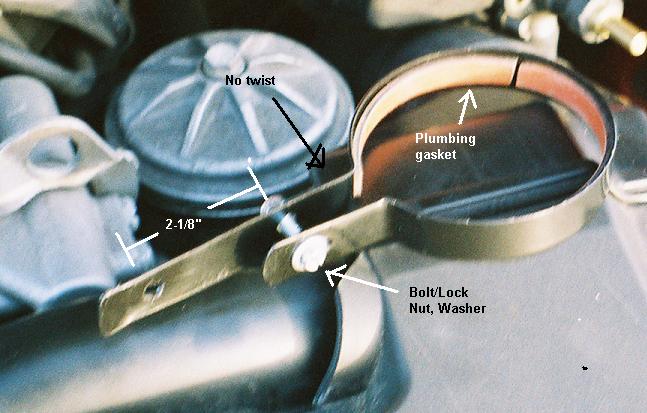

18) Remove the fuel line from the front side of the fuel rail. Note that this is secured with a one-time clamp, like the other fuel line clamps, so you’ll need to use new ones for the install.

19) Remove the brake booster vacuum line at the manifold. Again, you will need a new clamp.

Mine just pulled off and pushed back on. No need to replace or diddle with the clamp.

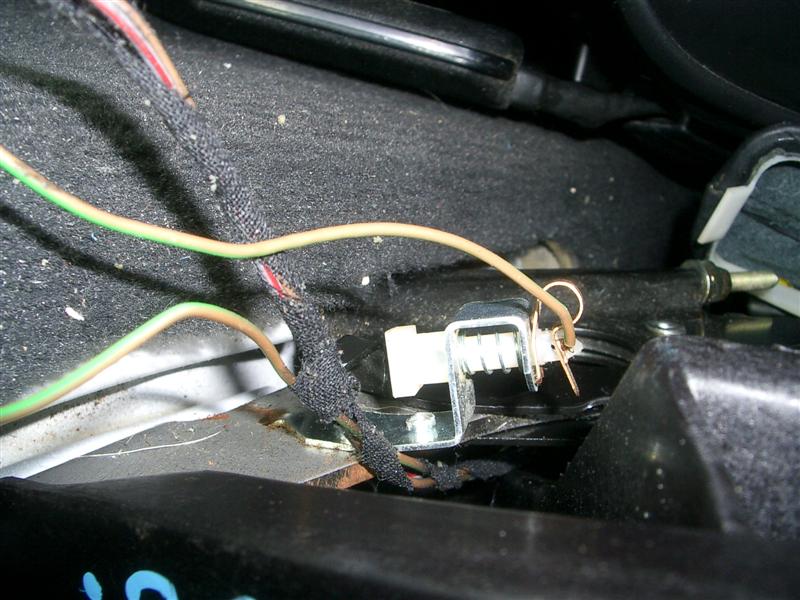

20) Remove the vacuum line at the fuel pressure regulator (no tools required, just pull it off).

I had to replace this hose. It was old and hard and rotten. A real pain.

21) Remove the wire that runs to the fuel injection harness from the Vanos securing bolt.

22) Remove the nuts securing the wire harness box and fuel injection rail to the manifold.

23) Remove the restraining clips that anchor the coil wires to the valve cover to gain a little freedom of movement in the fuel injection harness.

24) Next, you need to remove the fuel rail/harness/injectors from the manifold as an assembly (they stay together as a unit). However, you will note that you have not yet removed the rear fuel line at the fuel rail. This is because the rubber hose is so short that it lacks the flexibility to pull off the rail with the fuel rail in place. So, as you remove the rail/harness/injectors from the manifold, you will simultaneously pull the fuel line off the rear of the rail. Work slowly, and remove the rail/harness/injectors off the manifold by pulling upward. Set the assembly back over the valve cover as far as it will go and secure with temporary cable-ties.

This is a bit tricky - the injectors are plastic and fragile (and $70-80 each!). You need to be gentle in removing and reinstalling and even in how you sit it aside. I did tie it off, but I placed it on a towel. This is another area where taking the lower cowl out makes a big difference in freedom of movement. Some people take 1 or 2 injectors out to help. I left them all in.

25) Unclip the hard fuel line from the front underside of the manifold.

26) Unscrew the retaining nuts on the manifold.

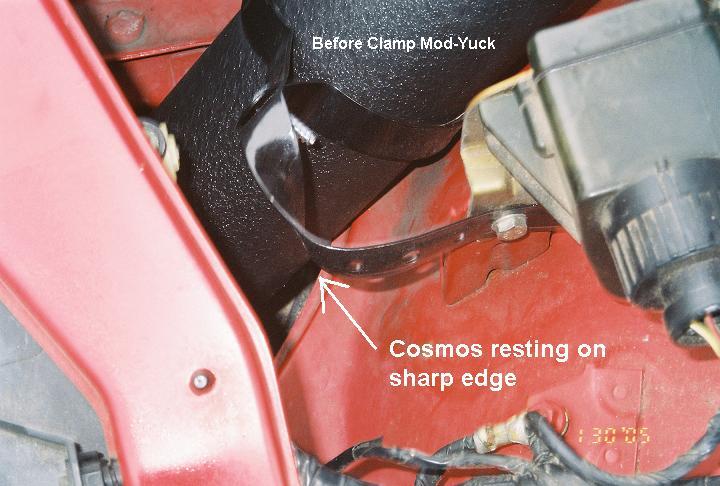

These are 11mm nuts and access to the 7th in the rear is made feasible by removing the lower cowl.

27) Pull the manifold from the cylinder head.

Before you do this, blow the grit and dust off to keep particles from falling in your intake ports. As you begin pulling it off, reach under the manifold and disconnect the electrical connector from the Intake Air Temp sensor. The intake manifold should now be in your hands. The only thing dangling from it should be the vacuum line to the pressure regulator.

Removing the manifold requires even pulls across the whole length of it. It takes patience.

28) Take this opportunity to inspect your intake valves. Mine had no significant carbon deposits! Gotta love Mobil gas with regular shots of Techron!

Cover the intake openings with clean shop towels to prevent crap from getting in there while open.

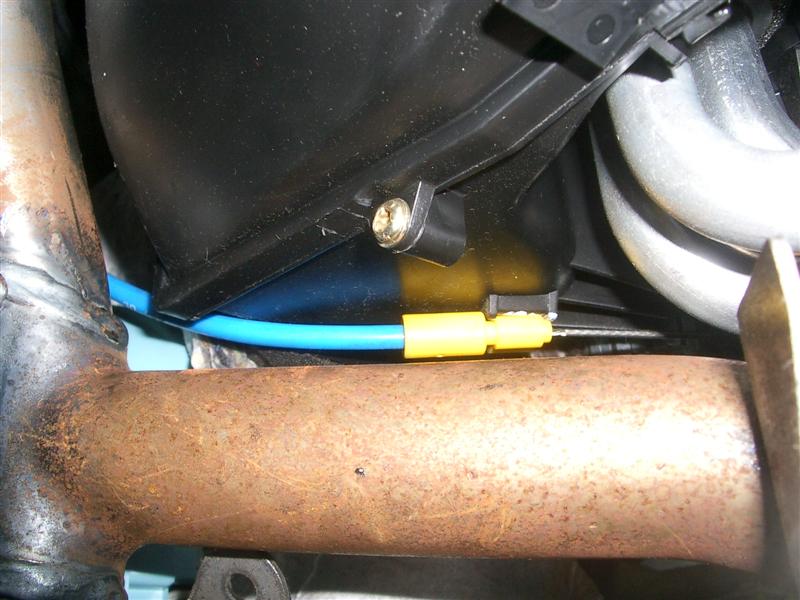

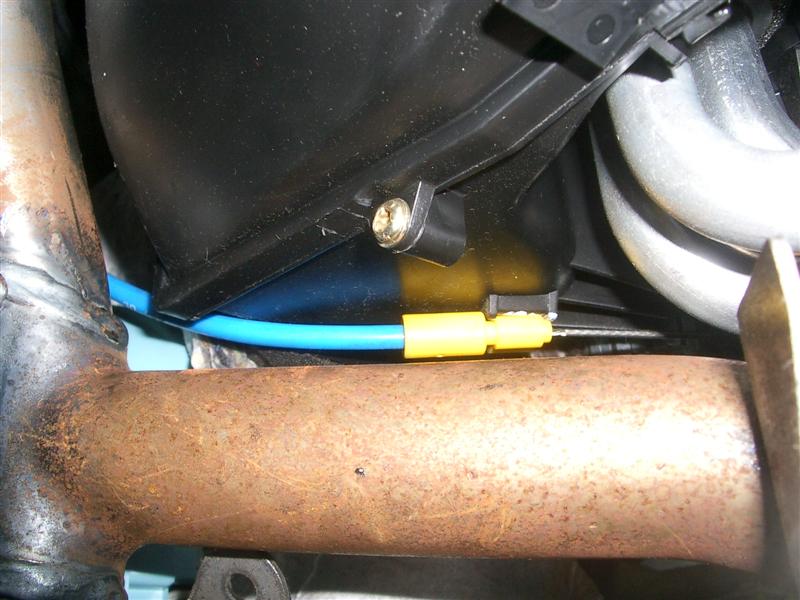

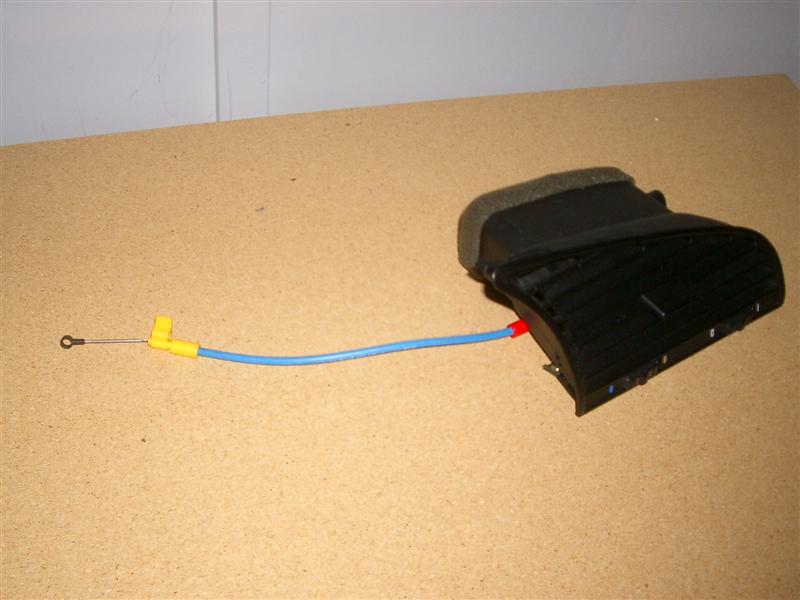

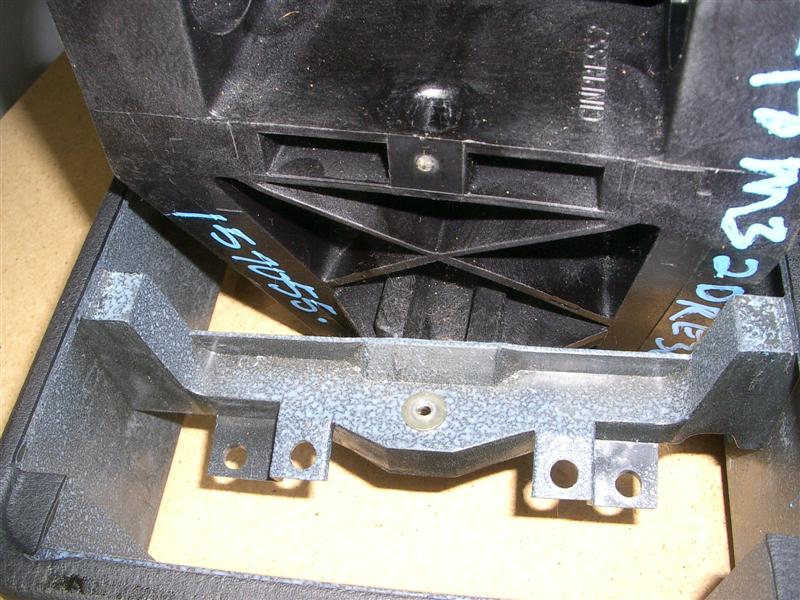

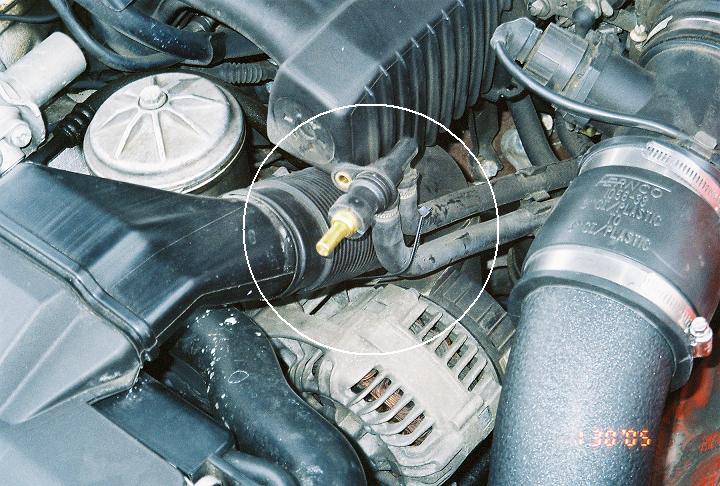

28a) Significant addition: In my car, I could see the knock sensor heads, but not the connectors. I had to remove the ICV to expose the connector portions (and even then it took some time to figure out which connectors belonged the knock sensors.) So - remove the ICV. A good time to clean it out and get rid of that erratic idle that 95 M3's seemed to have. (at least mine did). I also replaced my fuel filter at this time.

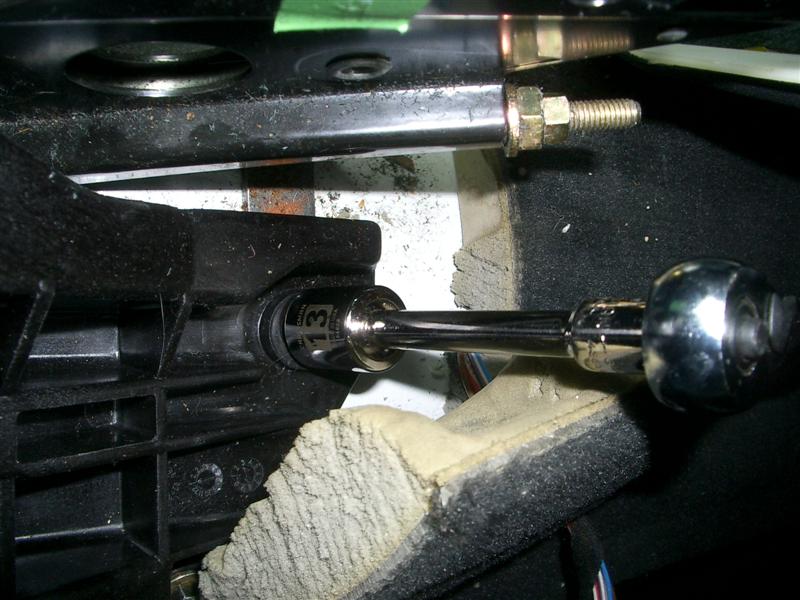

29) Remove the Number 1 knock sensor and wire connector,

noting the orientation of the sensor on the mounting boss. Clean the mounting surface, and replace with a new sensor. Use a torque wrench and torque to 15 ft-lb.

You have to feed the sensor connector behind some other stuff to get it in place.

30) To get to the Number 2 sensor, you need to remove a bracket that sits over it. Once that is done, replace the sensor like you did on Number 1.

31) Replace the intake manifold and throttle-body gaskets and lube with petroleum jelly. Lube the fuel injectors o-rings, as well as any vacuum line fittings with rubber-type sealing rings.

32) Reassemble reversing the steps above.

The biggest headache that I had on reassembly was rebolting the brackets to the bottom of the manifold. Two things helped: 1) don't tighten the manifold to the engine completely - allow some give. 2) loosen (but don't remove!) the lower mounting bolt on the bracket (esp rear) to allow some extra given while you blindly line it up with the hole on the manifold.

33) Let the fuel pump run a while before starting the car. Use this opportunity to reset any stored codes with your Peake Reset tool. If you don’t have one, I believe the stored codes will clear after 10 starts (assuming no additional faults). It may take several attempts to get the car to start. When it does, the idle may be erratic, but it will soon settle down and be smooth once the DME adapts.

It took 3 tries to start, but when it did it ran very smoothly.

34) That’s it! Enjoy life without those annoying CE light flashes!

Agreed!! Could not have done it without these instructions. Thanks RogRacer!!!!!!